LED Feedback

It can be hard to tell which part of your program the robot is running when your programs have multiple steps.

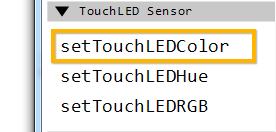

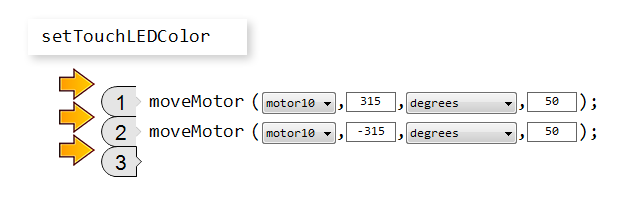

| The program runs in sequential order, from top to bottom. Depending on where setTouchLEDColor is placed, the Touch LED can react to how the arm motor moves. |

Did you know?

Gearing |

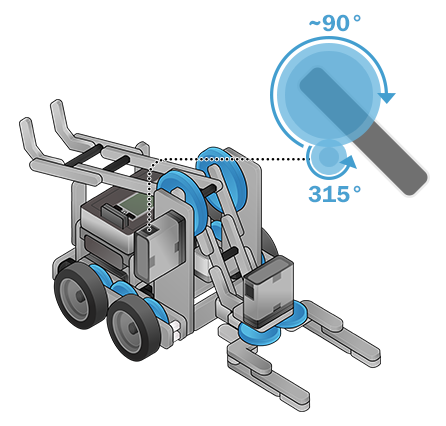

The arm motor needs to turn 315 degrees to move the arm between the up and down positions, but the arm itself does not move 315 degrees.

|

Did you know?

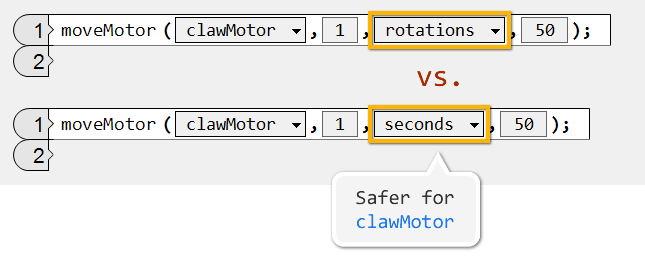

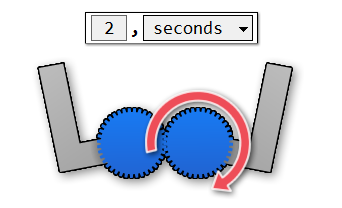

How to Avoid Claw Motor Getting Stuck

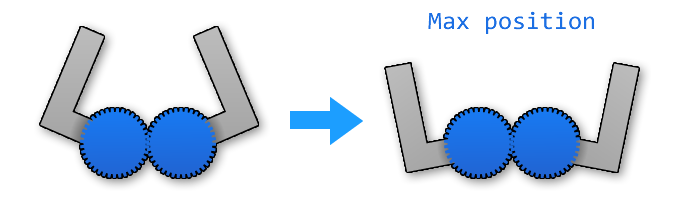

When controlling the Claw motor with the moveMotor command block, you should consider using seconds (or milliseconds) as the unit type. By choosing timing, you will prevent a scenario where the moveMotor command block cannot complete its movement and halts the program flow. Consider this scenario: The VEX IQ claw is already opened to its max position.

|

|

|

The robot must finish 2 rotations of rotation on the claw

no matter what, even if the claw cannot be opened any farther!

When this happens, your robot will be stuck on the moveMotor block forever. To stop the robot, simply terminate the program. |

|

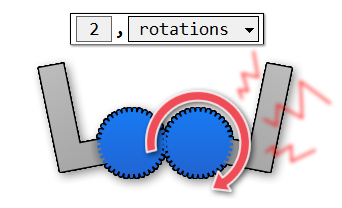

If "2 seconds" is used as the stopping condition, the robot will

still try to open the claw farther, but this time, the robot

will try it only for 2 seconds.

After 2 seconds, the robot will give up, and the program moves onto the next command block. |

Mini Challenge 2: Gripper Control

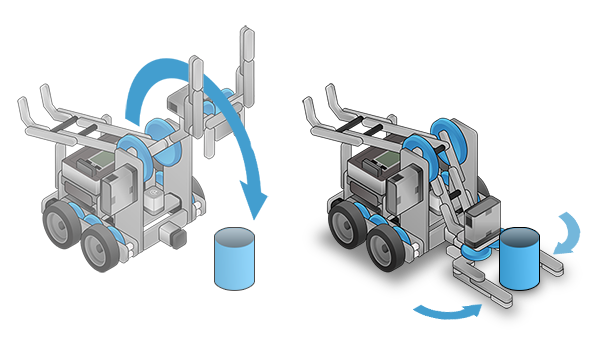

Program your robot to travel to the object, lower it’s arm, and grab it with the gripper. The gripper "hand" motor is on Port 11 on your robot.

|

You will need the robot to lower its arm and close its gripper, in that order.

It takes a small amount of degrees to close the gripper on the object.

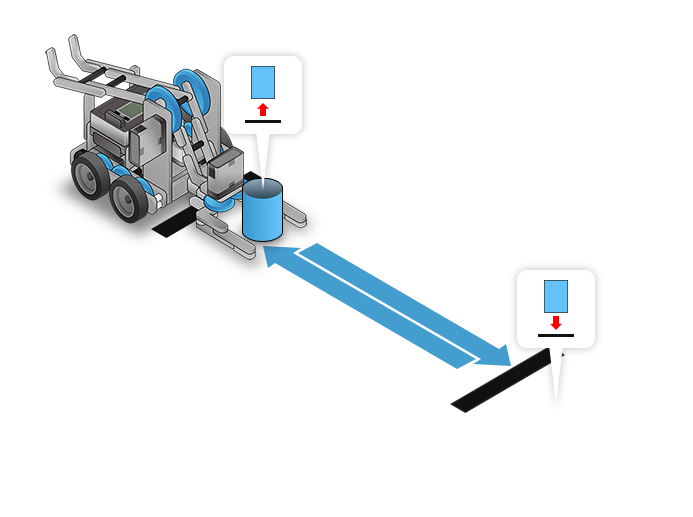

Mini Challenge 3: Cargo Transport

Program your robot to pick up the object in front of it, then carry it 85 cm, drop the object, and back up to its starting point.

|

Try writing down the actions the robot will need to perform, in the order that they need to occur. Then add commands to the program for the robot to do those things in the same order..

Don't try to close the gripper for a set number of rotations. If the gripper can't close any tighter, it will get stuck and never complete the command. Use time instead so it squeezes for a set amount of time, then remains closed in place.